CRYSTAL GROWTH furnaces

for laboratory

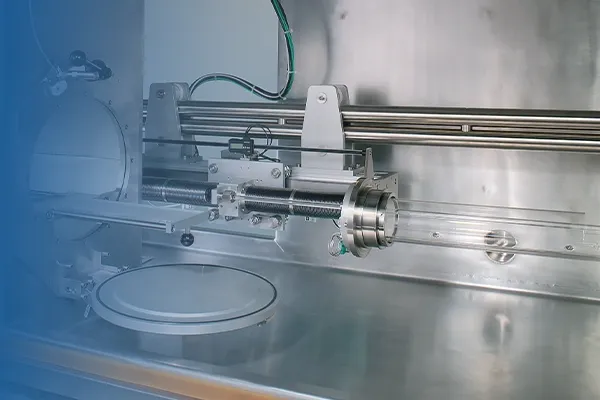

Crystal Growth Furnace, Precision

Equipment for Laboratory.

Our crystal growth furnaces are engineered for researchers and scientists who require exceptional control over crystal growth parameters. Designed for laboratories and R&D centers, these furnaces support advanced crystal growth methods such as Bridgman, Czochralski, LPE, and other specialized techniques.

Our full range of

Crystal Growth furnaces

Common Crystal Growth

Methods.

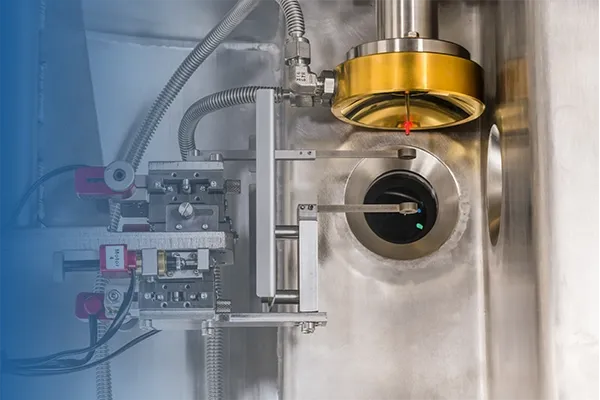

Czochralski

Czochralski crystal growth process is currently the most commonly used method to grow single crystals for a wide range of materials as oxides, metals, semiconductors. The method allows the production of relatively large single crystal reproducing the same crystalline orientation of the seed.

The exact time and temperature depends on the material itself, on the amount of prior cold work, solute concentration, and type of the desired annealing treatment. The final shape and quality of the crystal is directly related to the process parameters and the reliability of the equipment.

This line of equipment offers a high precision control of all process parameters through a dedicated control software with continuous data plotting and recording, suitable for laboratories as well as R&D centers.

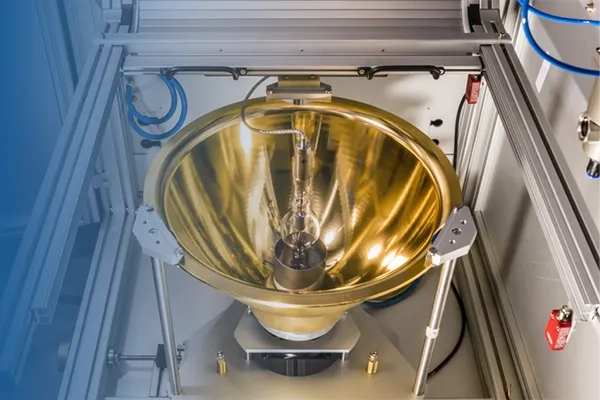

Kyropoulos

The Kyropoulos method is primarily used for growing large optical crystals, especially sapphire. A seed crystal is placed just below the surface of the molten material and slowly raised while carefully controlling the cooling rate. This technique minimizes thermal stress and internal defects, enabling the growth of massive, high-optical-quality crystals.

It is highly valued in laboratory and R&D environments for producing materials used in lasers, infrared optics, and high-strength transparent components.

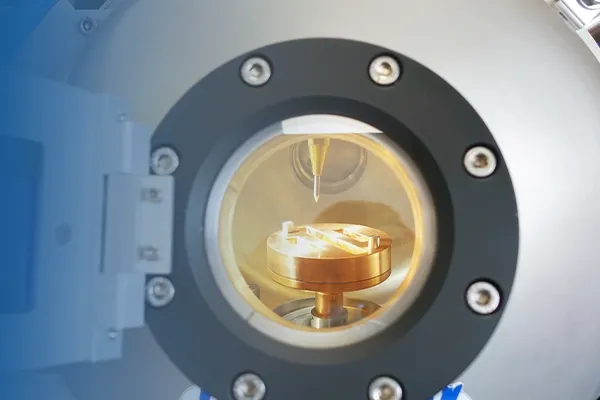

Bridgman

In the Bridgman method, powdered or molten material is placed in a container (often a crucible) and slowly moved through a controlled temperature gradient. As the material cools and solidifies from one end to the other, a single crystal forms. This method offers excellent control over crystal orientation and is well suited for semiconductors, infrared detector materials, and specialized alloys.

It is widely used in research settings for its reliability and adaptability to different materials.

Do you have a question or a project ?

Would you like more information, to entrust us with a project or meet our teams ? Fill in our form and our teams will get back to you as soon as possible!