GLASS-TO-METAL SEALING

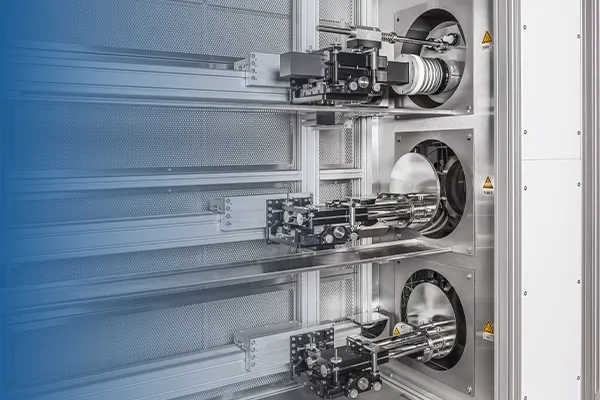

Our Glass-to-metal sealing

furnaces

Liliput

Hearth lift vacuum

furnace

Allow high added value applications for heat treatment.

Tubestar

Batch type horizontal

furnace

A Batch type tube furnace for RTP and deposition processes.

Turquoise

Vacuum horizontal

furnace

For oxidation-sensitive alloys such as nickel, titanium, etc.

ECM Lab solutions furnaces For

glass-to-metal applications :

In order to solve the problem of mechanical stresses in the seal (metals generally have a linear thermal expansion coefficient considerably greater than typical borosilicate glasses), the ECM Lab Solutions offers several furnaces for glass to metal sealing with oxidation (for surface preparation) and thermal treatment.

Because of high added value applications and very compact dimensions, our range of vacuum furnaces are perfect for laboratory and R&D environment.

How does Glass-to-metal sealing work ?

Glass-to-metal seals starting with the early Houskeeper or Vacuum tube seals, and advancing to elaborate SOFC fuel cells, and beyond.

Glass to metal sealing are made with metals or alloys having a value of coefficient of linear thermal expansion very close to that of the glass used in the temperature range comprised between ambient temperature and the glass annealing one.

Why using glass-to-metal sealing ?

Glass-to-metal sealing creates a perfectly sealed package for electrical or optical components. Often used to provide reliable, long-lasting protection for electronic devices. This process isolates and prevents infiltration that could damage components.

This process allows to create parts that are highly resistant.

Glass-to-metal sealing is used in several industrial applications : automotive, optoelectronic packaging, medical industry, nuclear, etc..

Do you have a question or a project ?

Would you like more information, to entrust us with a project or meet our teams ? Fill in our form and our teams will get back to you as soon as possible!