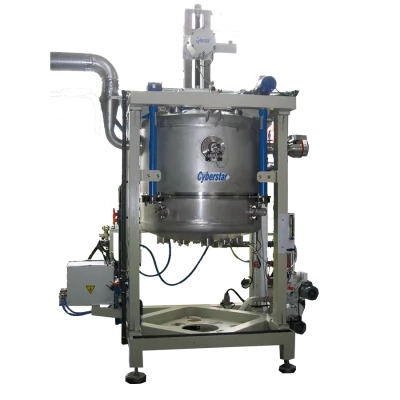

Technical specifications

Features

- Precise pressure regulation system

- Equipped with quartz (or sapphire) window view ports

- Operating security loop system

- Chambre capabilities for primary and secondary vacuum

- Various crystal sizes up to 100 Kg capability

Cyberstar precise pulling head

Translation speed from 0.01 mm/h to 100 mm/h and in fast mode up to 100 mm/min

Water cooled

Working temperature in the reactor up to 2600°C

Robotic integration

Robotics integration : with ECM Robotics

Effective dimensions

Ø 180 mm

Options

- possibility to operate under high pressure

- Weighing device up to 60 Kg

- Added crucible translation (manual or automatic)

- Controlled mass flow of different atmosphere gases

Industry

- Medical Imagery

- LED

- PV

- Solid Lasers

- Sensors

- Telecommunications

- Defense

Material

- SoG c-Si

- Sapphire

- III-V

- II-VI

- Ge

- Silicon

- LSO

- InSb