Technical specifications

Features

- Chamber capacities for primary and secondary vacuum

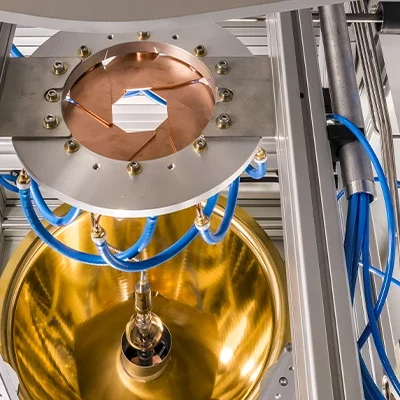

- Equipped with quartz (or sapphire) window viewports

- Operating security loop system

Temperature up to 3000°C

- MF2400 is dedicated to working temperature up to 2400°C

- MF3000 is dedicated to working temperature up to 3000°C

Atmospheres

- Vacuum

- Inert gas

- Reductive and oxidizing atmospheres

Sample

Volume : approximately 5 mm long for a diameter of 5 mm

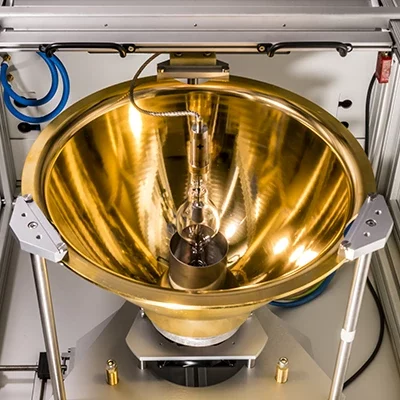

Temperature : high as 2400°C can be reached with two 2kW lamps

Precise and synchronized upper and lower translations

With a resolution up to 0.01 mm/h

Water cooled

Working temperature in the reactor up to 3000°C

Robotic integration

Robotics integration : with ECM Robotics

Effective dimensions

Ø : 3 to 10 mm crystal rode or fiber

Options

- Maximum operating gas pressure chamber 100 bars

- High magnification camera for full monitoring and recording of the growth process

- Pyrometer for localizaed temperature measurement

Industry

- Solid Lasers

- Sensors

Material

- Oxides

- Ceramics

- Semiconductors