Rapid Thermal Processing Equipment

Our Rapid thermal processing equipment

Jetfirst

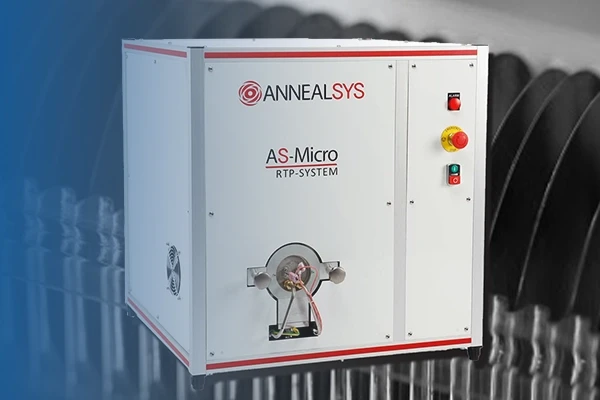

Bench top RTP

furnace

Rapid Thermal Prcessing furnace for laboratory and production.

Jetstar

Standalone RTP

furnace

Standalone RTP furnace with multi-zone control system.

AS-Premium

Rapid Thermal Processing System

RTP furnace : processing of silicon and compound wafers.

What is a rapid thermal processing furnace ?

Rapid Thermal Processing (RTP) consists in using lamp furnaces for rapid heat treatments on silicon wafers.

RTP is a semiconductor manufacturing process which provides a way to rapidly heat samples to high temperatures to perform short processes on a timescale of a few minutes maximum.

Fast heating and cooling to process temperatures up to 1400°C with ramp rates typically higher than 200°C/sec, combined with excellent gas ambient control, are within one processing recipe.

This system used to activate or dope the electronic layers by a very fast temperature raise up to 1200°C for proposed in complement of thin layers measurement systems.

Such rapid heating rates are performed by high intensity lamps (e.g. near-infrared light sources – Tungsten-halogen lamps) controlled by pyrometer and thermocouples that measure the sample temperature.

Do you have a question or a project ?

Would you like more information, to entrust us with a project or meet our teams ? Fill in our form and our teams will get back to you as soon as possible!